HIAB HYDRAULIC PUMPS & OIL TANKS

|

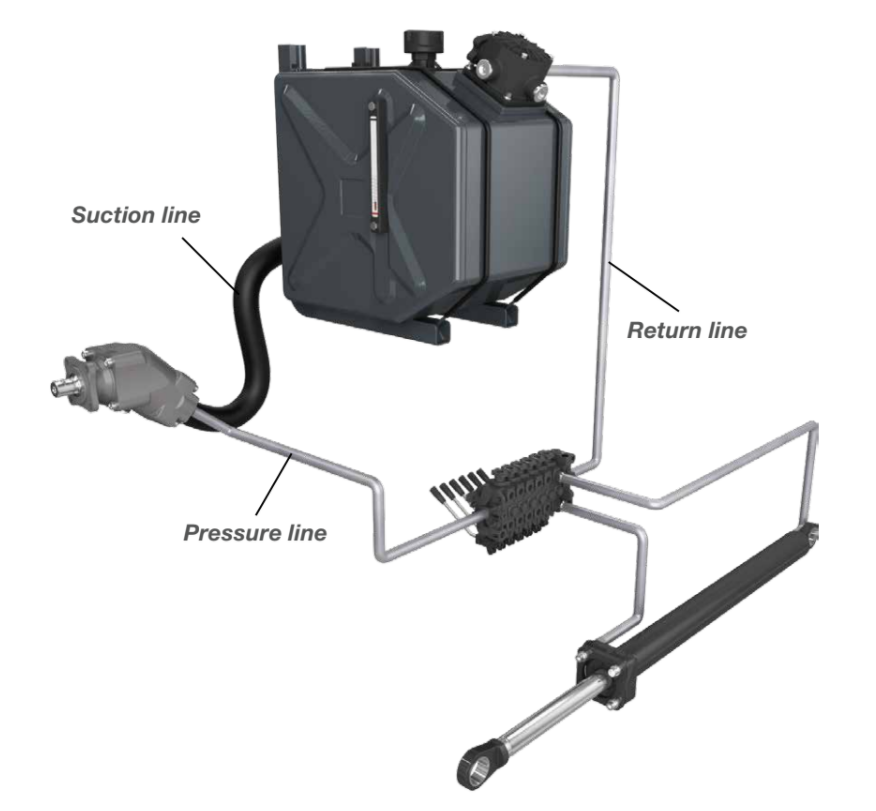

A hydraulic cycle |

View Cyclone Tanks View Oil Tanks View Hydraulic Pumps

The size of the oil tank required depends on a number of factors:

- The size and type of crane (for miscellaneous goods, forestry or recycling)

- If the crane uses hydraulic tools or just a hook

- If it has a load-sensing or fixed pump system

- If an oil cooler is fitted

- The climate in which the crane is to be used (North or South Europe, North America, Asia etc).

When using only hooks a general principle is that the net volume of the tank should not be less than 1.5 to 2 times the crane’s recommended oil flow. For a crane with hydraulic tools and/or a jib the size correspondence should be 2.0 to 2.5. When considering a pump it is important to choose the correct direction of rotation – which, in turn, depends on the direction of rotation of the power supply. The rotation of the power supply can be seen inside the output flange, or, for a pump on the “out” axle. Markings for the direction of rotation are – “R” for right and “L” for left – and are clearly visible when looking at the end of an axle. Rotation of the pump and power supply have to have opposite directions.

In other words, when the power supply is marked “R” the pump must be marked “L” in order to match.

The robust roller bearing unit in fixed pumps permits direct fitting on the motor-driven power supply without the need for a supportive roller bearing unit. For our variable pumps SVH, A18VO and VP1 we recommend a power supply fitted with a supporting roller bearing unit. In addition the high tare-weight torque of variable pumps often require support for the pump. All our pumps with denotation SVH or A18VO require having a pressure relief valve installed. This is not a requirement for other pumps but, we recommend that a pressure relief valve should be installed.